Your Carton Is Your Food Packaging's Life!

By John Henry, www.changeover.com

If your product is sold in a carton, it's one of your most important marketing tools. It is what your customer sees in the store and on the kitchen shelf. Your carton is worth its weight in gold and needs to be treated as such because a good-looking carton sells your product. A poor-looking one may deter consumers and end up being the reason they choose your competitor's product. I'll leave it up to the graphic-arts types to handle the aesthetics. In this article I will address some of the physical aspects that can detract from your carton's appearance.

There are a number of issues to watch out for; some are carton design and converting issues, others are cartoning machine issues. Cartons are most-commonly made from bending grade paperboard. Some cartons are made from corrugated board or plastic film. Whatever the material, it needs to be properly scored, glued, and diecut.

Two issues can occur with scoring:

- The scores can be improperly positioned. This can occur when the board or the scoring die slips out of position during the converting process. The carton always wants to fold on the score line and if it is out of position, it will not fold correctly. This will cause problems in the cartoner. If the unsquared carton makes it through the cartoner, it may cause appearance problems on the shelf.

- The score lines may not be deep enough or properly formed. This is also a problem at the converter. Bad scores will cause folding problems at the converter, when the blank is folded, as well as on the packaging line when the carton is erected.

There are a couple of issues that can occur with glue on cartons:

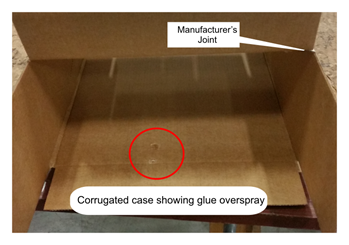

- All cartons have a "manufacturer's joint" where the carton is glued into a tube. If the converter is not careful, some of this glue can slop onto the inside of the carton itself, effectively gluing the blank together. Even a small drop of glue can prevent the carton opening properly, causing a cartoning machine jam.

- Many cartons are glued rather than tucked closed. If the carton has a varnished finish, there can be issues with the glue adhering. This may be apparent on the plant floor. In some cases it seems to adhere properly but then comes apart on the store shelf. When cartons are to be glued, it is a good idea to provide an unvarnished area on the flaps to help assure proper adhesion.

- There are over 200 types of hot-melt glues available and none are universal. Heat, cold, high or low humidity, and other conditions can affect glue performance. Consult your supplier to make sure that you are using the most appropriate glue.

One way to test glue effectiveness is to open the carton and look at the flaps. If the glue is holding correctly, you will tear the board rather than release the glue. If you don't see the tearing, you are not getting good adhesion.

Other cartoning issues include:

- Paperboard is like a sponge, absorbing moisture from the air. This makes it less stiff. In a dry environment, it releases moisture. This can make it hard to fold. All paper products should be stored in a controlled environment to keep the moisture content stable.

- When designing windows into a carton, keep their size and position in mind. If the window is close to an edge, the carton may fold on the window rather than on the score line.

- After scoring and folding, the carton blank is glued along the manufacturer's joint. It is critical for appearance, as well as running in the plant that this joint be properly aligned. Improper alignment will cause both aesthetic and cartoning issues. Cartons often need to fit tightly in a corrugated case. In severe instances, an improper joint can prevent a proper fit leading to issues at the case packer.

Cartons are how your product talks to your customer. Pay attention to the details and what your potential customer will hear is, "Buy me, please.” Trying to save money by purchasing cheaper cartons may be a false economy. The pennies saved, may result in lost sales and manufacturing inefficiencies.

About The Author

John Henry has worked in packaging since 1976 and is known as the go-to guy for information on packaging machinery. He is the author of the “Packaging Machinery Handbook” and “Secrets of Buying Packaging Machinery” and has authored more than 60 related articles in the trade press. At his consultancy, www.changeover.com, Henry focuses on helping manufacturers reduce downtime and improve operating efficiency. Got a question, comment, or column idea? He can be reached at johnhenry@changeover.com