Taffy's Metalized Film Wrapper Displays Good Taste

Table of Contents

Vacuum Metalization

First Commercial Use of Triophane

'Candy-Friendly' Film

Special Wrapper for Special Taffy

Premium. Value-added. Gourmet. In other words, not your average, run-of-the-mill candy. These are the images Glade's Taffy Town Inc. (formerly Glade Candy Co.) wanted to conjure up in consumers' minds when the Salt Lake City company decided to launch its new line of taffy candies.

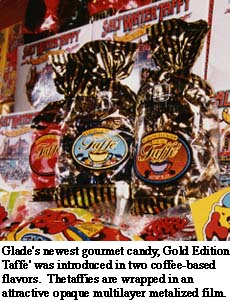

Using new, coffee-based flavors along with its traditional recipe and value-added packaging, the candy maker's new gourmet Gold Edition Taffé products have been well received by department stores and independent gourmet food and gift shops, says company president David Glade. The upscale taffies, targeted at adult candy lovers, were officially unveiled last summer at the NCA All Candy Expo in Chicago.

The key to Glade's marketing strategy, says Glade, is Triophane, a multi-layered film developed by Multifilm Packaging Corp., an Elgin, IL, division of Teich AG.

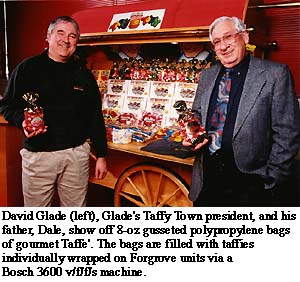

"Our goal for our new Taffé line is to create a gourmet image," explains Dale Glade, David's father and past president of the company, who is now retired. "The wrapper must be sharp looking."

"Satisfying the need for a premium, adult-flavored taffy is a natural progression for us," Dale continues. David Glade says the new line takes the company into a new market focused on older, more mature consumers.

The first two new flavors are coffee vanilla nut and coffee chocolate cream. They are packaged in blue-and-gold and brown-and-gold metalized film wrappers, respectively.

Vacuum Metalization

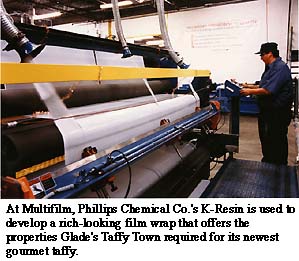

Using K-Resin styrene-butadiene copolymer (SBC) from Phillips Chemical Co. as a base, Triophane film is metalized in a vacuum process at Multifilm. "Our goal is to offer an alternative to cellophane in this type of application," explained David Von Huben, Multifilm's vice president of sales and marketing at the time of the launch of Glade's Gold Edition Taffé.

In the world of taffy candy, "cellophane rules," says David Glade. "We wanted something opaque, something upscale."

"Our metalization process provides marketing appeal and barrier, while the K-Resin is the key for machineability," noted Von Huben. "The K-Resin provides more deadfold to keep the twist sealed, and our proprietary coatings provide a release barrier so the taffy doesn't stick to the wrapper." Von Huben added that Multifilm sees a strong market in stick packs, individually folded and wrapped candies.

At Glade's Taffy Town, the different flavored candies are prepared in the kitchen and brought to the production line where the batter is extruded, cut and wrapped on seven lines consisting mostly of Forgrove units from England. Dale Glade says the units, while manufactured in the late 1950s, are still more than capable of wrapping the thousands of individual candies that the company produces daily.

Founded in 1916 by David Glade's grandfather, the candy company now has 70 different flavors of taffy in many designs. The type of packaging was a key decision when Glade decided to introduce the new, upscale line.

"Without premium packaging — design, colors and structure — we wouldn't have gone on with the project," affirms David Glade.

The outer bag is made from polypropylene and is supplied by Burns Packaging Products, a small Cincinnati-based company. Wrapped candies are automatically weighed on an Ishida 14-head scale and funneled to a Bosch 3600 vertical/form/fill/seal machine. The Gold Edition 8-oz gusseted standup bag is closed with a gold clip; the candies are also sold in bulk 5-lb bags. The filled bags are then case packed manually on a Stanley-Bostitch unit. The 5-lb bulk bags are shipped in 20-lb cases.

First Commercial Use of Triophane

Multifilm converts, metalizes, prints and slits film in its Elgin, IL, plant. The company also develops and formulates its own film structures, specializing in packaging for the candy industry. Multifilm has fold and seal wrap products, several different types of cast twist wrap and its Triophane film.

Glade's Taffy Town was the first commercial user of Triophane. In addition to metalized, Triophane is available in clear and white.

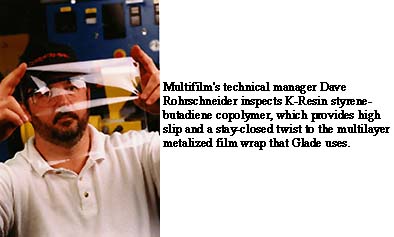

"Triophane is a unique material with high slip and high clarity and has an excellent natural twist that stays twisted mainly due to the use of K-Resin SBC," says Dave Rohrschneider, technical manager at Multifilm, who developed the product. Rohrschneider says Multifilm spent more than 2-1/2 years developing the recipe for Triophane.

K-Resin is the trademark for Phillip Chemical Co.'s line of clear, styrene-butadiene copolymers, which the company developed in the early 1970s. Today, the K-Resin SBC plant at the Phillips Houston Chemical Complex has a nameplate capacity of 370 million pounds.

‘Candy-Friendly' Film

"Currently, we're using K-Resin grade DK11 and found it to be the solution to the major obstacle of trying to coextrude non-compatible resins," says Rohrschneider. "The result is a highly modified cast polypropylene film with properties that closely match cellophane. Triophane also possesses high gloss and high stiffness, making it easy to work with and ‘candy-friendly'."

The K-Resin grade has an improved thermostabilization package that eliminates gels, which is crucial in the metalization process, according to Rohrschneider. Any contaminants in the resin will result in pinholes and flaws in the final package, which will be found only after the film is extruded and metalized. "We could waste a lot of material," he notes.

The union of materials and packaging came together when Glade's Taffy Town was searching for a new package with a premium look for its new Taffé line.

"The eye appeal was very high on Glade's list of requirements for the candy wrapper," said Von Huben. "Triophane has a very high gloss, almost like a polyurethane-varnished floor. This gloss further enhances the shine of the metalization and the two-color print."

Multifilm started its metalization line in 1995. In this process, a thin layer of aluminum is added to the film under extreme vacuum. While the chamber temperature drops to –195°F, white-hot metal is evaporated onto the cold film. The result is a material with a brilliant shine and excellent barrier properties.

The 10-year-old Multifilm plant runs three 8-hour shifts five days a week and has nearly 50 employees. The facility is ISO 9002 qualified.

Von Huben said Triophane provides a greater throughput for candy wrapping machines. "In the past few years, we've seen production rates go from 300 pieces per minute to 1,200 pieces and even 1,500 pieces per minute. The film must be able to process at those speeds and securely hold the candy."

"We've also been told that Triophane can run on machinery that normally couldn't run any type of twist-wrap film," he added.

Special Wrapper for Special Taffy

There is a difference in taffy, says Dale Glade. "We use a very high percentage of egg whites, and we condition every batch of taffy by letting it cool naturally overnight," he says. "This gives our taffy a light, fluffy texture, vastly different from the standard, machine-mixed taffy most people are familiar with."

And through the use of Multifilm's Triophane film with K-Resin, consumers can easily recognize that the candy is indeed special.

For more information:

Multifilm Packaging Corp., Elgin, IL, Tel: 847-695-7600, Fax: 847-695-7645.

Phillips Chemical Co. , Houston, Tel: 800-53-RESIN or 281-244-3080.

Rose Forgrove Inc. , St. Charles, IL, Tel: 630-443-1317, Fax: 630-443-3985.

Heat and Control Inc. (Ishida), Hayward, CA, Tel: 800-227-5980, Fax: 510-259-0600.

Robert Bosch Corp., Packaging Machinery Division, Bridgman, MI, Tel: 616-466-4000, Fax: 616-466-4119.

Stanley-Bostitch, East Greenwich, RI, Tel: 401-884-2500, Fax: 401-885-3122.

Burns Packaging Products, Cincinnati, Tel: 513-541-4235.

Edited by Bill Noone