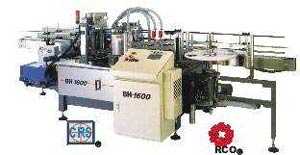

New Model 1600 Roll-Fed Labeler From B&H

Maximizes Production Flexibility Economically

The BH1600 is an economical new roll-fed labeler designed specifically for packaging operations with moderate production capacity requirements. The new BH1600 handles a wide range of container and label sizes and features B&H Rapid Change Over (RCO) capability to maximize production flexibility while minimizing production line downtime. The BH1600 provides optimum performance and reliability at an attractive price.

Ideal for beverage and aerosol packaging lines, the BH1600 labels containers ranging in size from 8 ounce (240ml) to 1.5 liters at speeds up to 300 cpm. The BH1600 also handles a broad range of household and personal care containers from 1.5 to 5 inches (3.8 cm - 13 cm) in diameter.

The latest model in the B&H family of Rapid Change Over (RCO) labelers, the BH1600 maximizes productivity by allowing container size and label changeovers to be performed by one employee in 15 to 20 minutes. Quick release handles, minimal change parts, and fewer required adjustments result in greater operational simplicity.

The BH1600 offers superior container handling and label control to ensure labeling accuracy. The patented Computerized Registration System (CRS) automatically maintains optimum registration, adjusting to variations in label length. The CRS uses an advanced photo-eye sensor that monitors the registration marks on the film and automatically adjusts the label feed to ensure the labels are correctly cut every time.

B&H designed the BH1600 to accommodate a variety of container types and accurately handle a wide array of label substrates, such as polyethylene, polypropylene, PVC, and clear polystyrene with variable machinability. B&H cooperates with multinational film suppliers, as well as packagers who manufacture their own films, to assure that B&H labeling equipment consistently performs to the highest standards of excellence with any label material.

The BH1600 features a computerized operating system that can be pre-programmed for different container and label sizes thus simplifying changeovers and eliminating operator errors. Operators simply push a button to set the vacuum drum, cutting drum, and glue application systems for positive container and label control. Designed with a user-friendly touch-screen control panel, the BH1600 simplifies operations and reduces operator training requirements.

Designed for years of continuous use, the BH1600 roll-fed labeler boosts productivity and decreases maintenance with a heavy-duty gear arrangement, precise cutting system, and accurate glue application system.

Located in Ceres, California, B&H Labeling Systems introduced the first viable roll-fed label application system in 1969. B&H is known worldwide for innovative, solution-driven engineering, high quality workmanship, and the unequaled reliability of its equipment. B&H maintains global representation to offer service and technical support to its worldwide customer base.