Wine Industry Toasts New Synthetic Wine Cork

Neocork Technologies uses Dow's AFFINITY POP resins as key material in what could be revolutionary wine industry breakthrough.

Neocork Technologies uses Dow's AFFINITY POP resins as key material in what could be revolutionary wine industry breakthrough.

Table of Contents

In Search of a Better Way

Material with the Right Stuff

Consistent Composition

So Far, So Good

Combining tradition with technology, a new coextruded resin wine cork from Neocork Technologies Inc. — developed with help from a consortium of wine industry players — may make traditional, natural wine corks a thing of the past.

Aided by the technical and financial assistance of Beringer Wine Estates, Clos du Bois, Kendall-Jackson Vineyards, Robert Mondavi and Turner Road Vintners, Neocork has produced a synthetic cork that, although it closely resembles a natural cork, differs from the traditional cork in several key ways. The new cork won't break upon opening a wine bottle, ensuring users a positive wine-opening experience virtually every time, and it also guards against cork contamination. The cork provides these attributes while preserving the tradition of wine presentation.

Three years in the making, Neocork synthetic corks are produced using AFFINITY polyolefin plastomer (POP) resins from Dow Plastics (Midland, MI). The new corks serve as a reliable alternative to natural cork, which, although it's been used to seal wine bottles for centuries, has been known to contribute to wine flavor contamination and can crumble and break apart upon removal, as many amateur wine drinkers and hurried waiters can attest.

In Search of a Better Way

Based in Napa, CA, Neocork Technologies was founded in 1996 with a single purpose, according to president Andrew Starr. The company was formed "with the concept that there needs to be a cork-like alternative that is technically superior to natural cork," he says. Natural cork stoppers — though perceived to be the marker of a premium wine — sometimes present problems for winemakers and consumers alike. Taint, or 2,4,6-trichloroanisole, commonly known as TCA, can result from microbes resident in the natural cork or the chemical process used to treat wood prior to making the cork stopper. TCA, which occurs randomly and can hamper even the most expensive corks, affects wine by imparting a "musty" or otherwise "off" flavor.

Since natural cork contamination cannot be detected until a bottle is opened and most consumers think that the vintage and/or brand, not the cork, is the cause of the problem, brand equity may be compromised as consumers may resist buying that brand in the future. "Natural corks have a product failure rate of up to 8%, which is not acceptable in other beverage industries," says Dr. Stuart Yaniger, Neocork's chief technical officer. He notes that soft drink manufacturers operate near Six Sigma defect levels, or one defect per million.

Natural cork also tends to break during removal, which could cause consumers to purchase alternative, non-corked beverages. Neocork, along with others in the wine industry, felt it was time to develop a new closure that could not only ensure the quality of wine products but preserve the ritual of the cork-pulling tradition.

Being a Napa, CA, company led by experienced winemakers — including Starr, Yaniger and chairman/CEO Peter Stern, a leading expert on producing premium kosher wines — Neocork partnered with wineries that currently manufacture 25% of the corked-finished wine in the United States. These companies provided design and technical input to Neocork Technologies, which then developed a list of key product performance criteria necessary for the wine bottle closures but still needed help with the material and manufacturing process.

Material with the Right Stuff

"We required that the material provide a good seal, be non-absorbent and resilient, have compatibility with existing bottle-corking machinery and be easily extracted by the consumer," says Yaniger. "The synthetic cork also had to be very inert, not imparting any off-flavor or off-odor to the wine." Neocork had known of AFFINITY POP's use in food and specialty packaging applications and liked its performance capabilities, such as flexibility and neutral odor and flavor.

AFFINITY POPs, made via Dow's patented INSITE single-site, constrained geometry catalyst and solution process technology, met the cork application requirements. The AFFINITY resins used in the synthetic corks have the necessary toughness to prevent the cork from breaking apart or crumbling and have no off-taste or off-odor characteristics. As engineered materials, they are biologically sterile to eliminate the possibility of taint. Additionally, AFFINITY POPs offer the same oxygen transmission rates (OTR) as natural wood corks and are FDA-compliant for direct food contact.

"We were in constant contact with Dow Technical Service & Development (TS&D), and it became an interactive effort," says Yaniger. "Not only did they help us evaluate which type of AFFINITY resin to use, but also how it should be processed. They also gave recommendations as to who could foam and extrude the product for us as well."

Consistent Composition

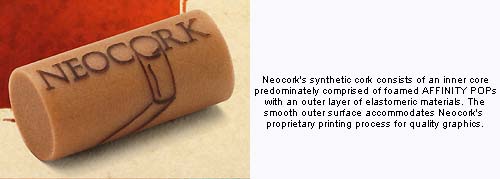

To produce the cork required that it be able to be compressed and expanded at a certain rate, making the resin selection crucial. The correct blowing agent to foam the resin was also important. The final product is a synthetic cork with an inner core predominately comprised of foamed AFFINITY POPs with an outer layer of elastomeric materials. The smooth outer surface enables Neocork Technologies Inc. to incorporate its proprietary printing process for quality graphics or a company name or logo to be branded on the side for vineyard or winery identification.

The new cork is produced using a profile extrusion process whereby the foamed resins are extruded as one continuous part, then cut to the appropriate size. This process, says Yaniger, creates a uniform cell structure and density consistent throughout the cork, assuring identical composition in all corks.

This consistency gives the AFFINITY resin corks advantages over injection-molded synthetic corks, which have hit the marketplace with mixed results. Such advantages include the elimination of cell structure and density variables, which are sometimes found in injection-molded corks. In addition, unlike injection-molded corks, there is no rigid skin around the Neocork corks, making them easier to insert a corkscrew and pull the cork from the bottle. Much like a natural cork, the Neocork cork provides a celebratory "pop" when pulled from the bottle, giving consumers the enjoyment from opening a wine bottle they have traditionally experienced.

So Far, So Good

Neocork has evaluated the cork's performance through a variety of tests, including corking and extracting, taste and aroma, microbiological and stability with a wine's chemistry, and reports positive results. Yaniger says the cork can be used by winemakers "universally." To date, Neocork Technologies has made global commercial shipments to 22 wineries. The corks are priced competitively with current wine corks on the market, says Neocork.

For more information:

Neocork Technologies Inc., American Canyon, CA, Tel: 707-642-6800.

Dow Chemical Customer Information Group, Midland, MI, Tel: 800-441-4369.

Edited by Bill Noone